Wire and Rod Rigging

Did you know? PTR is one of only two shops in the Northwest capable of swaging larger wire sizes. PTR is also capable of straightening and heading rod rigging up to -40.

What is swaging?

Swaging is a metal-forming technique in which the metal is plastically deformed to its final shape using high pressures, either by pressing or hammering, or by forcing through a die. Swaging differs from forging in that the swaged metal is cold worked, and the output of the swaging operation is usually the finished shape.

Swaging actually improves grain structure giving the part greater strength and an usually fine finish.

About our swage machine

Port Townsend Rigging has a roll and rotary swage machine. All swages are filled with polysulfide and measured to ensure that swages conform to Military specification tolerances.

Roll

- Dies leave "flash" lines

- Machines are less expensive, more portable, more common than rotary

Rotary

- Perfectly smooth swage

- Large "heavy industrial", high volume

Standing rigging 1/4" and above is usually done on our Fenn 4F machine. Lifelines and standing rigging through 7/32" are usually done on our Kearny roll machine.

Wire

Port Townsend Rigging has a roll and rotary swage machine. All swages are filled with polysulfide and measured to ensure that swages conform to Military Specification tolerances.

1x19 Wire - Type 316SS

7-Strand Wire - Type 316SS (7x19)

Lifeline Wire - White Vinyl Coated Type 316SS (7x7)

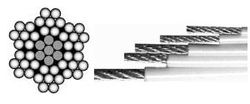

Rod Rigging

Rod or solid stainless rigging offers low elongation, superior strength to weight and longevity over stainless wire rigging. It is standard on many high end yachts such as Valients, J Boats, and Swans.

PTR purchased a rod header and straightener in 2005. Rod rigging is a highly specialized form of solid rigging that requires a deep skill set to produce expertly. PTR has the capacity to straighten and head rod from -04 to -40.

How to Tension Your Sailboat Rigging

Contact info

All Rights Reserved | Port Townsend Rigging